Memnagar, Ahmedabad, Gujarat

- GST NO. : 24AACCJ8925G1ZJ

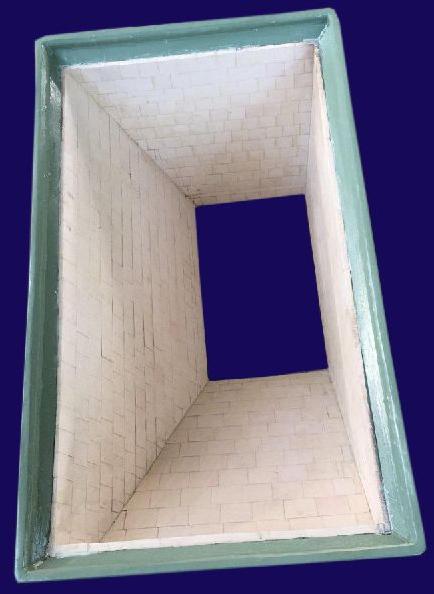

Industrial Chute

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Abrasion Resistant Coatings, Building Adhesive, Ceramic Chutes, Ceramic Cyclones, Ceramic Hopper, Grinding Media Ball, High Alumina Ceramic Products, Jyoti Aluminium Epoxy Putty, Jyoti Antifouling Paint, Mild Steel Bending Pipe Ceramic Lined Bends, Slag Chute With Liner and Spiral Chute from Ahmedabad.

JTBC-SL-99 is a trowelable, epoxy-based ceramic compound specially engineered to provide exceptional wear and abrasion resistance in heavy-duty industrial applications. This high-strength compound is ideal for resurfacing and protecting metal, rubber, and concrete surfaces exposed to continuous impact, sliding, or particle abrasion.

The trowelable grade allows easy manual application over vertical and horizontal surfaces without sagging, making it perfect for on-site repairs and protective lining.

Features of Abrasion Resistant Coating:

-

Exceptional Wear Resistance

-

Designed to protect surfaces from abrasion, erosion, and corrosion, ensuring longer lifespan of equipment exposed to harsh conditions.

-

-

High Durability

-

Resists wear from slurry, gravel, sand, and other abrasive materials, making it ideal for industries like mining, cement, and power generation.

-

-

Enhanced Protection for Equipment

-

Ideal for pumps, chutes, conveyors, and piping systems subjected to high mechanical stress, providing a protective shield that minimizes damage.

-

-

Impact Resistance

-

Forms a tough surface that withstands high-impact forces, protecting critical equipment from physical damage in high-velocity applications.

-

-

Chemical and Corrosion Resistance

-

Offers protection against harsh chemicals, acids, alkalis, and salts, ensuring longevity in aggressive environments

-

Easy Application

-

The trowelable or sprayable grade ensures easy manual application, making it suitable for vertical and horizontal surfaces without sagging. This is ideal for on-site repairs and maintenance.

-

-

Reduced Downtime

-

Protects surfaces from wear and tear, reducing the need for frequent repairs and replacements, and minimizing downtime in industrial operations.

-

-

Cost-Effective Solution

-

Provides a cost-effective solution for extending the life of equipment and avoiding expensive replacements in industries dealing with abrasives.

-

-

Thermal Stability

-

Resistant to high temperatures, making it suitable for equipment exposed to elevated operating conditions in industries like steel production and thermal power plants.

-

-

Versatility

-

Suitable for use on a wide range of materials including metal, ceramic, rubber, and concrete, offering versatility for various industrial applications.

-

-

Long-Lasting Finish

-

Once applied, the coating forms a long-lasting bond that does not easily degrade, even under the most abrasive and corrosive conditions.

-

-

Reduced Maintenance Costs

-

Prolongs equipment lifespan by providing a protective layer, thereby reducing the overall maintenance costs over time.

-

-

-

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer |

| Country of Origin | India |

| Type | Adhesives |

| Material | Adhesive |

| Purity | 90% |

We are manufacture High Alumina Ceramic Lined . It is Wear Resistant Products. It's Remove abrasion and protect the based Products

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer |

| Country of Origin | India |

| Type | Chute Conveyors |

| Application | Industrial |

| Condition | New |

life comperision

f 2 times more than high chrome/ni-hard

f 3 times more than cast chrome alloy

f 3 times more than cast basalt

f 4 times more than abrasion resistance steel

f 8 times more than stainless steel

f 15 times more than mild steel

f 43 times more than polyurethane

industrail application

sleeve, mechanical seal, plunger, pipe, burner nozzle, ferrule tube, washers, thermocouple sheath, thread guide, pulley, ceramic rod, bearings, valves, impeller, crucibles, bush and many more places where the matter is wear, temperature, erosion, and corrosion.

different quality

f aluminum oxide – 92%

f aluminium oxide – 90% brown

f aluminum oxide – 90 – 99.7%

f zirconium

f zta

f mullite

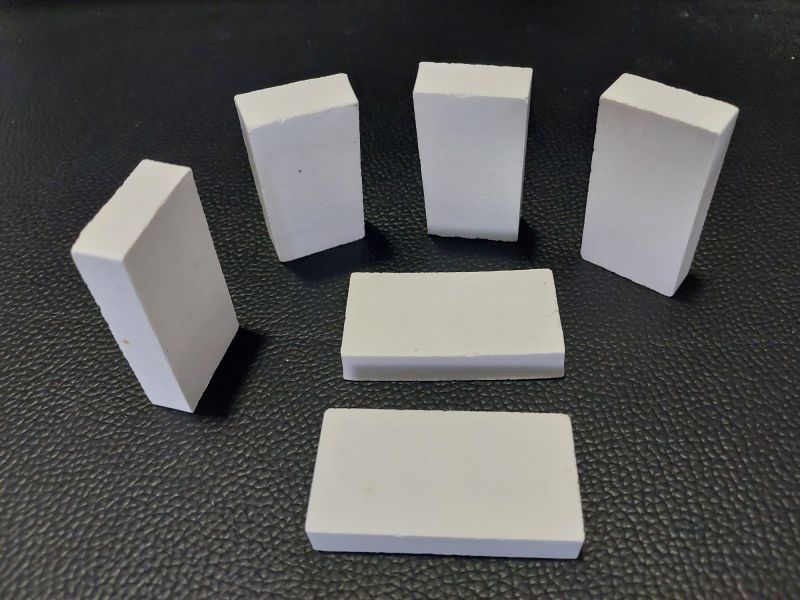

f silicon carbide

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer |

| Brand Name | TORRID |

| Material | Ceramic |

| Application | Instrial |

| Size | 1000 Piece |

| Type | Ceramic, Ceramic |

| Country of Origin | India |

| Packaging Type | Bucket |

| Finished Surface | Smooth |

| Port | Ahmedabad |

| Payment Terms | Other |

| Delivery Time | 2-3 Days |

industrial application:

- sleeve, mechanical seal, plunger

- pipe, burner nozzle, ferrule tube

- washers, thermocouple sheath

- thread guide, pulley

- ceramic rod, bearings

- valves, impeller, crucibles

different quality:

- aluminum oxide - 92%

- aluminium oxide - 90% brown

- aluminum oxide - 90 - 99.7%

- zirconium

- zta

- mullite

- silicon carbide

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer |

| Brand Name | Torrid |

| Color | White |

| Type | Industrial Vibrators, Industrial Vibrating Machine,Ceramic |

| Country of Origin | India |

| Condition | Used |

| Automatic Grade | Semi Automatic |

| Packaging Type | Bucket |

| Finished Surface | Hard |

| Port | Ahmedabad |

| Payment Terms | Other |

| Delivery Time | 2-3 Days |

| Packaging Details | JYOTI INNOVISION PRIVATE LIMITED PLOT NO. 7 ,N.K . 3 INDUSTRIAL PARK , BAKROL - BUJRANG,AHMEDABAD -382433 , GUJARAT. |

life comperision

f 2 times more than high chrome/ni-hard

f 3 times more than cast chrome alloy

f 3 times more than cast basalt

f 4 times more than abrasion resistance steel

f 8 times more than stainless steel

f 15 times more than mild steel

f 43 times more than polyurethane

industrail application

sleeve, mechanical seal, plunger, pipe, burner nozzle, ferrule tube, washers, thermocouple sheath, thread guide, pulley, ceramic rod, bearings, valves, impeller, crucibles, bush and many more places where the matter is wear, temperature, erosion, and corrosion.

different quality

f aluminum oxide – 92%

f aluminium oxide – 90% brown

f aluminum oxide – 90 – 99.7%

f zirconium

f zta

f mullite

f silicon carbide

.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer |

| Brand Name | Torrid |

| Finishing | Polished |

| Shape | Round |

| Color | White,White |

| Feature | Compact Designs, High Strength, Optimum Quality, Perfect Shape, Shiny Finish |

| Type | Grinding Media Ball, Ceramic |

| Country of Origin | India |

| Packaging Type | Bucket |

| Port | Ahmedabad |

| Payment Terms | Other |

| Delivery Time | 2-3 Days |

HIGH ALUMINA CERAMIC GRINDING MEDIA FOR BALL MILL, BEAD MILLING, ATRIETOR, it is developed for highly wear prone applications.

By using High alumina ceramic grinding media available sizes:

1-3mm

6mm

10mm

12mm

20mm

30mm

40mm

50mm

60mm

The Hardness of “ALUMINA GRINGING MEDIA” is next to diamond ( 9MOHS ) that indicates it is extremely hard material, proving itself as one of the best wear resistance materials. It lasts more than any other conventional material to take all abuse associated with bulk material handling. One addition benefit of the product is its high Wear Resistance properties & performance in a High Temperature / Corrosion environment.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer |

| Material | High Alumina |

| Finishing | Ceramic |

| Color | White, SUPER WHITE |

| Purity | 90% |

| Feature | Best Quality, Prefect Shape |

| Type | Alumina Ceramic |

| Country of Origin | India |

| Brand Name | TORRID |

| Temperature Range | 1525'C |

| Dimension | 50X25X10mm |

| Packaging Type | Bucket |

| Product Code | TORRID92 |

| Port | Ahmedabad |

| Payment Terms | Other |

| Delivery Time | 2-3 Days |

High Alumina Ceramic Liner 50*25*10mm

HIGH ALUMINA CERAMIC TILE LINERS & CERAMIC LINED PARTS are developed for highly wear prone applications such as Coal base unit, Mud Convey, Acid paste, Ash Handling, Mining, Cement, Steel, Ceramic, Mineral Processing units etc. The Hardness of JYOTI Liners is next to diamond that indicates it is extremely hard material, proving itself as one of the best wear resistance materials. It lasts more than any other conventional material to take all abuse associated with bulk material handling. One addition benefit of the product is its high Wear Resistance properties & performance in a High Temperature / Corrosion environment.

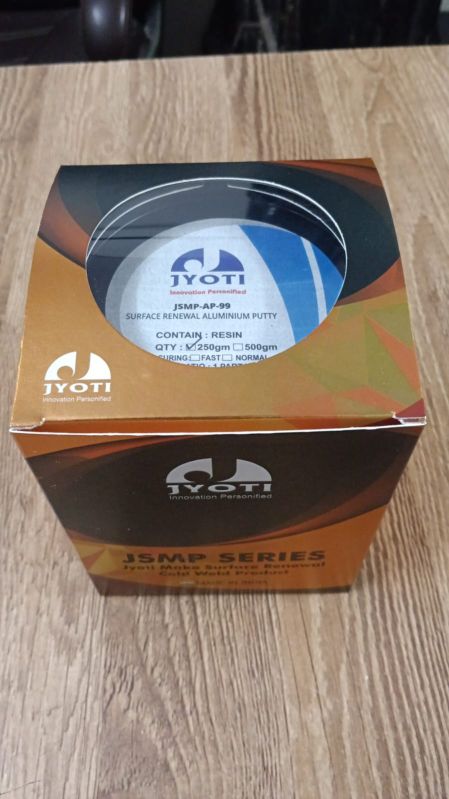

| Business Type | Manufacturer |

| Brand Name | JYOTI |

| Form | Liquid |

| Application | Construction |

| Surface of Application | Aluminium |

| Grade | Chemical Grade, Industrial Grade |

| Classification | Is An Aluminum-filled, Epoxy-based Material Designed To Cure At Room Temperature. It Is Specificall |

| CAS No. | 7429-90-5 |

| Country of Origin | India |

| Color | Silver |

| Product Code | JSMP-AP-99 |

| Port | AHMEDABAD |

| Payment Terms | Other |

| Delivery Time | 4-5 day |

| Packaging Details | Product Form: Two-component epoxy system (Base + Hardener) Standard Pack Sizes: • 1 kg set (500g Base + 500g Hardener) • 5 kg set (2.5 kg Base + 2.5 kg Hardener) • Customized bulk packaging available on request Packaging Type: • Leak-proof, high-strength HDPE or metal containers • Each component packed separately in labeled containers • Kit includes usage instructions and safety data sheet (SDS) Outer Packing: • Carton box or corrugated box with cushioning material • Suitable for export with proper sealing and batch identification Labeling: • Product Name, Code, Batch Number • Manufacturing Date, Expiry Date • Mixing Ratio and Basic Application Instructions • Safety Symbols (as per international guidelines) Shelf Life: 12 months from the date of manufacturing (when stored in original, sealed packaging under cool and dry conditions) Storage Conditions: • Store in a dry, shaded area • Keep away from direct sunlight, moisture, and extreme temperatures • Recommended storage temperature: 15°C – 30°C |

Jyoti Aluminum Putty (JSMP-AP-99) is a premium-grade, aluminum-filled, two-component epoxy repair compound developed for reliable, long-lasting repairs and maintenance of aluminum and other metal components. Engineered to cure at room temperature, JSMP-AP-99 is designed for industrial applications requiring strong adhesion, corrosion resistance, thermal endurance, and ease of application.

This high-performance putty bonds securely to aluminum, steel, cast iron, and other metal substrates. Once cured, it forms a solid, machinable surface capable of withstanding harsh environments and heavy mechanical loads. Whether you 're sealing leaks, rebuilding worn surfaces, patching cracks, or filling gaps—this solution delivers consistent and dependable performance without the need for heat or welding.

Key Features:

✅ Aluminum-Filled Formulation: Specifically developed to match the properties of aluminum parts, ensuring strength, compatibility, and long-term durability.

✅ Room Temperature Curing: No heat or special equipment required—cures efficiently at ambient temperatures, saving time and energy.

✅ Versatile Application: Can be applied to a wide range of substrates including aluminum, mild steel, stainless steel, cast iron, and even ceramic.

✅ Superior Bonding Strength: Provides strong adhesion to both ferrous and non-ferrous metal surfaces, reducing the chances of repair failure.

✅ Excellent Corrosion Resistance: Protects metal surfaces from oxidation, moisture, and chemical exposure—suitable for marine, industrial, and outdoor conditions.

✅ High-Temperature Resistance: Maintains strength and integrity even under elevated temperatures.

✅ Machinable After Curing: Once cured, the putty can be drilled, tapped, sanded, or machined to restore original part geometry.

✅ Cost-Effective and Reliable: A durable, multipurpose solution that reduces downtime and repair costs.

Applications:

🔧 Aluminum Component Repairs: Ideal for repairing and rebuilding damaged, corroded, or worn-out aluminum parts in machinery, automotive, aerospace, marine, and other sectors.

🔧 Leak Sealing & Surface Patchwork: Perfect for patching cracks and sealing leaks in tanks, pipes, casings, housings, and fittings.

🔧 Surface Restoration: Rebuild worn surfaces, fill holes, and restore surface integrity on structural and mechanical parts.

🔧 Preventive Maintenance: Extend equipment life by protecting vulnerable surfaces and joints from future wear and tear.

🔧 Cross-Material Compatibility: Suitable for use on multiple surfaces such as mild steel, stainless steel, cast iron, and even ceramic.

Typical Industries Served:

• Cement Plants

• Power Generation

• Marine & Shipbuilding

• Mining & Earthmoving

• Chemical & Fertilizer Processing

• Automotive & Transportation

• General Engineering & Maintenance

Mixing Ratio & Curing:

• Mix Ratio: Resin to Hardener (as supplied)

• Application Time: ~30 minutes (varies by temperature)

• Initial Curing: 4–6 hours at room temperature

• Full Cure: 24 hours for maximum strength

• Working Temperature Range: -30°C to +150°C

Packaging Available:

•1kg, 5kg kits (custom packaging available on request for bulk/industrial use)

Why Choose Jyoti Aluminum Putty (JSMP-AP-99)?

Jyoti Innovision Pvt. Ltd. has been a trusted name since 2009, delivering proven industrial solutions for abrasion resistance, corrosion protection, and cold welding across a wide range of industries. JSMP-AP-99 reflects our commitment to innovation, quality, and long-term customer satisfaction. Our epoxy repair products are trusted by engineers and maintenance professionals across the globe for their reliability and performance.

Export-Ready Advantages:

✔ Non-toxic, solvent-free formulation

✔ Long shelf life

✔ Easy logistics & safe packaging

✔ Custom labeling available for OEM or export clients

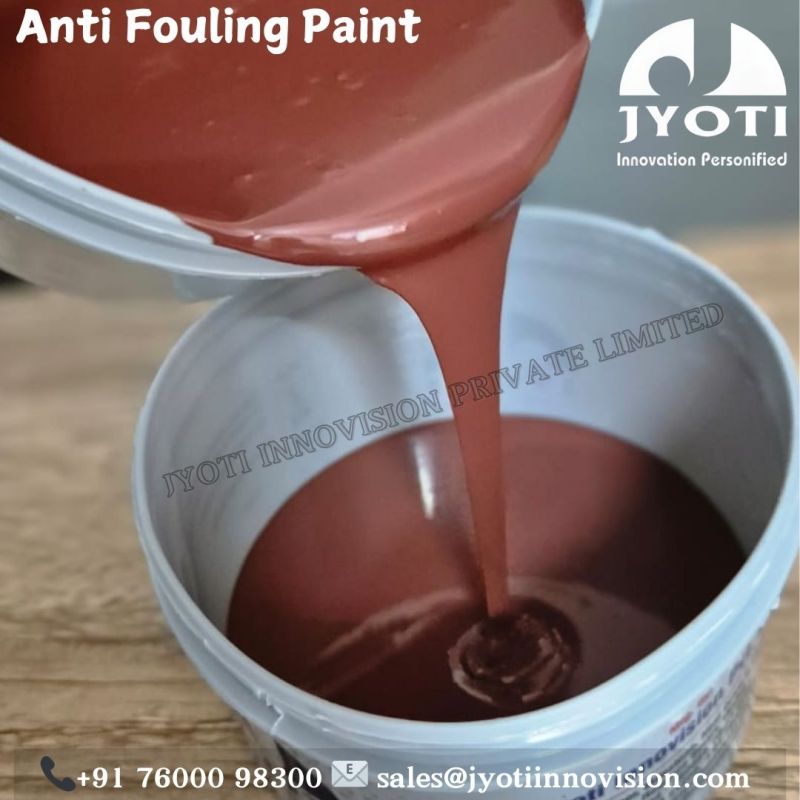

| Business Type | Manufacturer |

| Brand Name | JYOTI |

| Color | RED,Red |

| Application | Brush, Roller |

| CAS No. | 1317-39-1 |

| EINECS No. | 215-270-7 |

| Packaging Type | Can |

| Type | liquid |

| Country of Origin | India |

| Product Code | JB-AFC-90 |

| Port | Ahmedabad |

| Payment Terms | Other |

| Delivery Time | 4-5 day |

| Packaging Details | Packaging Details – Anti-Fouling Paint Product Name: Anti-Fouling Marine Paint Packaging Type: High-grade metal container Available Pack Sizes: 4 Litres 20 Litres Net Weight: As per selected pack size Shelf Life: 12 months in original sealed container Storage Conditions: Store in a cool, dry place Keep away from direct sunlight and moisture Ensure proper sealing after every use Labeling: Each container is clearly labeled with product name, batch number, manufacturing date, expiry date, usage instructions, safety precautions, and manufacturer's contact details Transportation: Packed securely in corrugated boxes (if required) for bulk handling Suitable for road, rail, and sea freight Handle with care – Flammable item |

Jyoti Anti-Fouling Paint is a high-performance coating specially developed to protect underwater and constantly wet surfaces from the buildup of marine organisms like algae, barnacles, and shellfish. It is suitable for use on ships, boats, underwater pipelines, offshore platforms, marine equipment, and steel or wooden structures exposed to sea or fresh water. This paint forms a durable, protective layer that resists the attachment of marine growth and fungus. It not only protects the surface but also improves operational efficiency by reducing maintenance frequency and increasing the life of your assets. With advanced formulation and easy-to-use application features, Jyoti Anti-Fouling Paint is the ideal choice for marine and industrial users looking for reliable, long-term protection. Key Features: ✅ Strong Adhesion: Bonds excellently with steel and wooden surfaces. ✅ Anti-Fungal Protection: Prevents fungal growth on submerged surfaces. ✅ Easy Application: Simple brushing or spraying method; no complicated steps. ✅ Quick Curing Time: Fast drying and curing, reducing downtime. ✅ Long-Term Effectiveness: Offers protection for up to 180 days in marine conditions. ✅ Smooth Finish: Leaves a clean surface that reduces drag and improves fuel efficiency for vessels. ✅ Environmentally Considerate: Designed to reduce harmful effects on marine ecosystems. Applications: Ships and boats (hulls, rudders, and propellers) Marine vessels and fishing boats Underwater pipes and marine machinery Oil rigs and offshore structures Water tanks and reservoirs Docks, harbors, and port structures Steel and wooden marine structures How It Works: When applied to a surface, Jyoti Anti-Fouling Paint forms a solid protective layer. This layer releases agents that prevent marine organisms from attaching and growing on the surface. The coating is resistant to constant water contact, sunlight, and temperature changes, ensuring reliable protection over time. Performance Life: ✔ Up to 180 days of effective anti-fouling protection in harsh marine conditions. ✔ Reduces the need for frequent cleaning and repainting. Advantages: Extends the service life of vessels and submerged structures Reduces maintenance and repair costs Improves fuel efficiency in ships by lowering surface drag Enhances safety and hygiene in water storage structures Easy to apply on new installations or as a maintenance coat Packaging & Storage: Available in sealed metal containers. Store in a cool, dry place away from direct sunlight and heat sources. Always stir well before application. Application Method: Surface must be cleaned and free of dust, grease, and old loose paint. Can be applied using brush, roller, or spray equipment. Apply in 1-2 coats as per surface exposure and requirements. Drying time may vary depending on humidity and temperature, but it usually cures quickly. Why Choose Jyoti Innovision’s Anti-Fouling Paint? At Jyoti Innovision Pvt. Ltd., we are committed to delivering innovative coating solutions that protect your assets and reduce operational costs. Our anti-fouling paint is the result of dedicated R&D and years of industry experience. Trusted by clients in marine, industrial, and offshore sectors, our coating ensures peace of mind with long-term performance. Export Information: HSN Code: 3208 (Paints and varnishes based on synthetic polymers) Country of Origin: India Minimum Order Quantity: As per client requirement E

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer |

| Country of Origin | India,Made in India |

| Brand Name | JYOTI |

| Material | Mild Steel |

| Finishing | Polished |

| Color | Red |

| Application | Industrial Ceramic,Chemical Handling Pipe |

| Shape | Bending pipe |

| Grade | Industrial |

| Delivery Time | 3 - 4 DAYS |

| Packaging Details | VARIOUS TYPE OF PACKING WITH DETAILS |

With the support of our experienced professionals, our company has established in this domain as a reputed manufacturer, exporter and supplier of Ceramic Lined Bends. These bends are hard and compact in designs. Our entire range of bends is properly coated with top class ceramic for utmost protection from corrosion and abrasion. These Ceramic Lined Bends are commonly use in industrial pipeline fitting for changing the pipe direction.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer |

| Material | Mild Steel, Stainless Steel, CERAMIC LINE |

| Finishing | Color Coated, WITH LINING |

| Color | Silver |

| Condition | New |

| Application | Concrete Mixing Use |

| Size | Customized |

| Feature | Durable, Fine Finished, High Performance, Long Service Life, Rust Proof |

| Type | Industrial Chute, Discharge Chute |

| Country of Origin | India |

| Brand | Jyoti |

| State | Solid |

| Application/Usage | Metal , Steel , Aluminum, Ceramic |

| Shape | Rectangle , Square |

| Surface Finish | Polished |

| Port | Ahmedabad |

| Payment Terms | Other |

| Delivery Time | 2-3 Days |

SPECIFICATIONS:

|

Size in MM |

LENGTH (MM) |

WIDTH (MM) |

THICKNESS RANGE (MM) |

SHAPE |

|

10X10 |

10 |

10 |

2.5-4 |

Square |

|

17.5X17.5 |

17 |

17 |

3-5 |

Square/Hex/Cylinder |

|

20X20 |

20 |

20 |

4-15 |

Square/hex/Cylinder |

|

20X20 DIMPLE |

20 |

20 |

4+1 |

Square + Pre-engg. |

|

25 X 25 |

25 |

25 |

4-15 |

Square/Hex/Cylinder |

|

25X25DIMPLE |

25 |

24 |

5+1 Dimple |

Square/Pre-Engg. |

|

50X25 |

50 |

25 |

6-20 |

Rectangle/Pre-engg. |

|

50X50 |

50 |

50 |

6-25 |

Square/Pre-Engg. |

|

75X50 |

75 |

50 |

8-30 |

Rectangle/Pre-engg. |

|

100X50 |

100 |

50 |

10-30 |

Rectangle/Pre-engg. |

|

150X100 |

150 |

100 |

12-30 |

Rectangle/Pre-engg. |

|

150X50 |

150 |

50 |

15-30 |

Rectangle/Pre-engg. |

|

190X100 |

190 |

100 |

15-30 |

Rectangle/Pre-engg. |

|

PROPERTIES |

TACPL92 |

|

Al2O3 |

92 + 2% |

|

SIO2 |

8 - 10% |

|

Color |

White |

|

Density |

3.6grm/cc |

|

Hardness Mohs |

9 |

|

Water Absorption |

NIL |

|

Porosity |

NIL |

|

Compressive strength |

198Mpa |

|

Flexural Strength |

32.5Mpa |

|

Wear & Chemical resistance – mg/cm2/day |

0.01 |

|

Thermal properties – No load count |

1520’C |

INDUSTRIAL APPLICATION:

Ball Mill, Ceramic Base plate, Sand Mixtures, Concrete Mixture, Bins, Hoppers, Chutes, Pipes, Bends, Y-Pieces, MDV, MOE, Orifices, Venturi Collar, Silo, Valves, Packing Line, Cyclones, Classifiers, Slag tubes, Hydro cyclone, Shafts, Sleeve, Casings, Separator, ID Fan, Equipment liner, Screw conveyer & many more places where abrasive material is Stored, Process, Transport or move in bulk.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | MS & Steel |

| Surface Finishing | Polished |

| Brand | Jyoti |

| Shape | Circle |

| Surface Finish | Polished |